The most commonly used pretreatment is known as “phosphating”.A phosphate coating is formed as a result of the reaction of a chemical solution with a metal.Phosphate is a layer-shaped form formed by iron, zinc and manganese crystals on the surface to be painted.

It can be applied in three ways as iron phosphate, Zinc Phosphate and manganese phosphate. As a rule, protective oils can be used before the paint is applied.It can be used in coating iron, steel and, in some cases, aluminum and zinc surfaces. The use of immersion and spray is common.Temperature, concentration, time, pH and total-free acid are the points to be considered. Phosphating process can be done at 35-70ºC temperature for 5-10 minutes and 3-5% concentrations because of phosphate type and process form. Phosphate coating reaction is considered an acid-base reaction as a result of melting the metal surface with phosphoric acid. An increase in pH is observed while this melting occurs. Metallic phosphate becomes insoluble on the metal and forms a metallic-colored structure.

5.Iron Phosphate and its applications

It is the oldest phosphating method. It is the easiest type of phosphate to apply, install and control. Not too exposed to corrosion ( chair and lighting fixtures, etc.) used for materials.Corrosion resistance is lower but more economical than other phosphate types. Colors from yellow to red can be formed on the Metal, mainly blue.Approximately 0,2-1,0 gr/m2 coating on the metal surface.Total acid, pH, temperature and duration are the parameters that need to be controlled.

Iron phosphate can be applied in 3 ways, manual wiping, dipping and spraying:

Manual Wiping Iron Phosphate

1/10 solution is prepared and used with cloth,sponge or brush. At the same time, it takes both its oil and phosphate is made.The effect of temperature will be positive. After the process is done, it is necessary to dry it with air or cloth. It is the most economical and simple method. Suitable for very large parts that can hold water.

Immersion Iron Phosphate

It is a classic method in which temperature, concentration and duration are effective. The first stage is degreasing bath. The oil-removed material enters the rinse in the second stage. Double rinsing is more convenient in terms of lack of transport. Since the pH of the first bath is 14 and the pH of the iron phosphate bath is 4-5, it is necessary for the minimum transport process (sludge, pH Rise and cost) to work under favorable conditions. The third stage is iron phosphate. Parts remain in the iron phosphate bath at 45-55 º C for 5-10 minutes and become phosphated. Then, after staying in the passivation bath for 30-45 seconds, the maximum 130º C will enter the paint after drying. It is the most appropriate time to be painted on the same day. Because iron phosphate is a thin coating, there is a risk of rust between 24 and 48 hours depending on weather conditions.decoction The point where corrosion resistance is highest is under the paint.

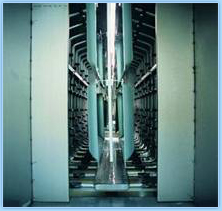

Spray Iron Phosphate

It is the newest option where temperature, concentration, pressure and duration are effective. Although the initial investment cost is high, it can cover the cost in a short time with quality and less chemical consumption. It can be used after an alkaline degreasing bath, and can be applied by entering neutral degreasing. It is possible to create a high quality phosphate layer in an environment where the temperature is 45-55 ºC, the pressure is 1.5-1.8 bar and the duration is 1.5 minutes. If the alkaline decontamination method is not to be used, chemicals with degreasing effect can be used in the iron phosphate bath. Bathroom options and cleaning methods vary according to operating conditions. Phosphated parts become painted after passivation and maximum drying of 130ºC.